India’s cities are growing fast, and with them, the challenge of managing municipal solid waste (MSW). Overflowing landfills, toxic emissions, and groundwater pollution are becoming everyday realities. But what if this waste could become a powerful tool for clean energy?

That’s exactly what Organic Recycling Systems Limited (ORS) has been demonstrating. Through advanced anaerobic digestion processes, innovative segregation lines, and technologies such as the MethanoBoost Catalyst (MBC), ORS is unlocking the potential of waste and biomass valorization to produce compressed biogas (CBG).

Why MSW-to-CBG Matters for India

- Urban Waste Burden: India produces over 62 million tonnes of MSW annually.

- Climate Impact: Methane from landfills contributes massively to global warming.

- Energy Security: As natural gas is a non-renewable resource, replacing non-renewable gas imports with CBG ensures energy independence.

- Circular Economy: By integrating and responsibly managing MSW processing, India can recycle resources, reduce emissions, and create value.

The Biogas Production Process

Anaerobic Digestion

The anaerobic digestion process uses microbes in production of biogas to break down organic matter without oxygen. The biogas production process steps include:

- Hydrolysis – organic polymers break down.

- Acidogenesis – acids and alcohols form.

- Acetogenesis – acetic acid and hydrogen are generated.

- Methanogenesis – methane-rich biogas is released.

These biogas production stages are influenced by factors affecting biogas production such as feedstock quality, temperature, microbial balance, and pH control.

From Biogas to CBG

Raw biogas is purified by removing CO₂, H₂S, and water vapor. The result is compressed biogas (CBG) with over 95% methane, a renewable alternative to CNG. Unlike non-renewable gas, CBG is fully sustainable and reduces carbon intensity.

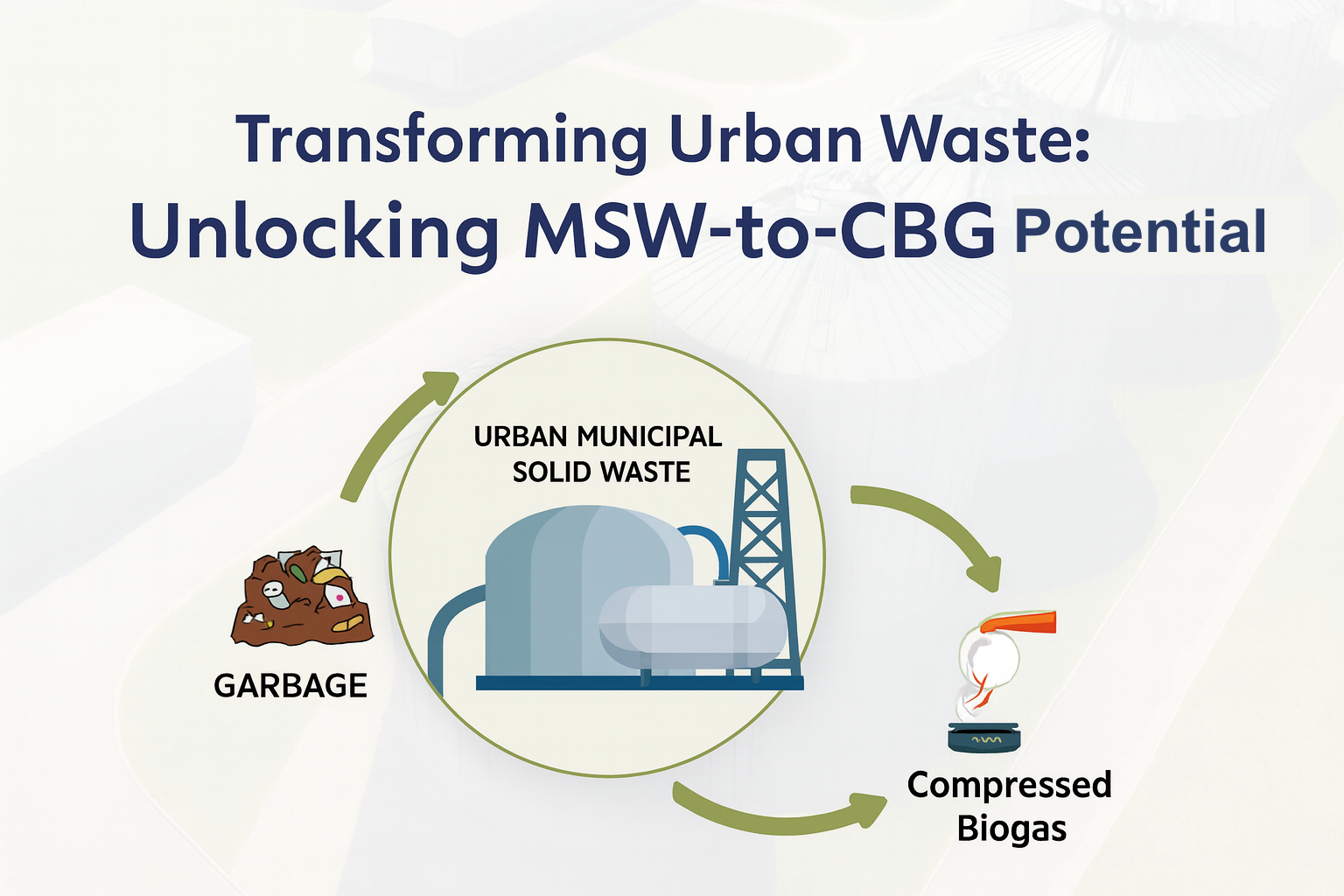

MSW to CBG: Transforming Urban Waste into Green Energy

One of the most promising pathways in India’s renewable energy transition is converting Municipal Solid Waste (MSW) into Compressed Biogas (CBG). Instead of letting organic fractions of waste end up in overflowing landfills, ORS technology channels them into sustainable biogas production plants.

Key Feedstock from MSW for CBG Plants

- MSW Organics – Food scraps, garden trimmings, and organic municipal waste are the core feedstock.

- Segregated Wet Waste – Ensures a consistent and clean input for the anaerobic digestion process.

- Bioenzymes & Microbes – Support faster decomposition, improving methane yield during biogas production stages.

- Digestate – A by-product of digestion, repurposed as organic fertilizer, contributing to waste valorization.

Why MSW to CBG Matters

- Reduces landfill dependency and methane emissions.

- Aligns with India’s SATAT Scheme to establish a nationwide CBG infrastructure.

- Provides a renewable substitute for natural gas, helping industries and transport reduce reliance on fossil fuels.

- Supports urban waste management while creating a circular economy.

With advanced waste-to-energy technologies, ORS ensures that MSW to CBG plants in India not only address the growing urban waste challenge but also contribute to the nation’s clean energy goals.

Solapur Bio-Energy Systems Private Limited (SBESPL)

ORS Innovation: MethanoBoost Catalyst (MBC)

ORS recently introduced MethanoBoost Catalyst, validated by SSS-NIBE, which improves methane yield by up to 30%. This breakthrough boosts the efficiency of the biogas production process especially when using challenging feedstock like paddy straw or mixed MSW.

This innovation significantly reduces CBG plant cost in India per unit of gas produced and positions ORS as a leader among biogas plant manufacturers in India.

Real-World Momentum: Case Studies

- ORS Solapur Plant – India’s first integrated MSW processing facility, handling 400 TPD of waste to generate CBG and organic manure, setting global benchmarks.

This project provides invaluable data for preparing CBG plant project reports, helping investors, policymakers, and engineering companies expand future projects.

Applications of CBG Beyond Transport

CBG isn’t just a fuel—it’s a multi-sector solution:

- Urban Transport – replaces CNG in buses, autos, and trucks.

- Industrial Heating – alternative to furnace oil and LPG.

- Fertilizer Production – digestate reduces chemical dependence.

- Sustainable Aviation Fuel – R&D is exploring conversion of biogas into next-gen jet fuels.

The Role of Engineering Companies

The success of CBG plants depends on strong collaborations with engineering companies for design, construction, and maintenance. With increasing demand, engineering companies in Mumbai like ORS are leading the charge by providing end-to-end cleantech solutions—from feasibility studies to commissioning.

Challenges and Opportunities

Challenges:

- Feedstock Consistency – mixed MSW and poor segregation.

- Technology Adoption – advanced anaerobic digestion wastewater treatment systems need higher investment.

- Cost Factor – financing large-scale projects given current CBG plant cost in India.

Opportunities:

- Government Support – SATAT incentives, carbon credits, and fiscal benefits.

- Biogas Plant Manufacturers – growing network across India ensures scalability.

- Community-Level Units – decentralized biogas production plants for kitchens, institutions, and localities.

Conclusion

Biogas production in India is no longer an experiment—it’s a proven pathway to sustainable growth. By managing MSW through anaerobic digestion process, India can replace non-renewable gas with a truly renewable resource.

As biogas plant manufacturers and engineering companies in Mumbai like ORS innovate with catalysts, enzymes, and optimized designs, the cost-efficiency of CBG is improving rapidly. With the SATAT scheme and public-private partnerships

From waste bins to fuel tanks India’s MSW-to-CBG revolution is here. ORS is proud to be leading this green transformation.

Connect with Organic Recycling Systems

📞 Contact: 022-41702222

✉️ Email: info@organicrecycling.co.in 💼 Connect with Us on LinkedIn!

1. What is the role of feedstock in biogas and CBG production?

Feedstock such as segregated organic waste, agricultural waste, municipal waste biomass, paddy straw, biomass waste, and Super Napier grass directly affects biogas output, methane yield, and efficiency of the anaerobic digestion process.

2. What is an anaerobic digester?

An anaerobic digester is a sealed bioreactor where microbes in the production of biogas break down biomass and organic waste. Different systems exist including mesophilic digesters, low-solid digesters, dry anaerobic digestion systems, and wet digesters used in MSW and agricultural waste management.

3. How does anaerobic digestion support sustainable waste management?

The anaerobic digestion process converts municipal waste, biomass, and agricultural waste into biogas, biomethane gas, and digestate, supporting solid waste management, waste recycling, waste reclamation, and waste and biomass valorization.

4. What types of biomass feedstock can be used in a biogas plant?

Common biogas feedstock includes:

-

Segregated organic MSW

-

Agricultural waste products

-

Biomass feedstock such as Napier grass, Super Napier grass, paddy straw

-

Food waste, organic waste from kitchens, markets

-

Industrial waste with biodegradable content

5. What is a CBG plant?

A Compressed Biogas (CBG) plant or Bio-CNG plant purifies raw biogas from a biomethanation plant to produce CBG, which is similar to natural gas but renewable. Many CBG plants in India operate under the SATAT scheme.

6. How does waste segregation impact biogas production?

Effective waste segregation, especially through dry waste segregation systems, adjustable waste screening systems, waste separators, and material recovery facilities, ensures cleaner feedstock and improves performance of a biogas production plant or waste processing plant.

7. What are the major steps in the biogas production process?

The biogas production process steps include:

-

Waste collection and waste audit

-

Sorting, waste processing, waste recycling

-

Feeding the anaerobic digester

-

Hydrolysis → Acidogenesis → Acetogenesis → Methanogenesis

-

Gas purification using filters, membranes, and gas valves

-

Compression to produce CBG

8. What is digestate and how is it used?

Digestate is the nutrient-rich by-product from the anaerobic digestion system. It is used in windrow composting, in-vessel composting, bio composting technology, and organic fertilizer production.

9. Can agricultural waste be used to generate renewable energy?

Yes. Agricultural waste management systems convert crop residues into biomass energy, biogas, biomethane production, biofuel production from agricultural waste, and renewable energy from agricultural waste.

10. Is natural gas a renewable resource?

Natural gas is not renewable. However, bio-gas is a renewable source of energy, and biomethane or CBG is a renewable alternative to natural gas.

11. What services do engineering companies provide for CBG projects?

Engineering companies, especially engineering companies in Mumbai, offer EPC services, PMC services, engineering services, feasibility reports, CBG plant project reports, laboratory services, and biogas consultancy services.

12. What is the SATAT Scheme?

SATAT (Sustainable Alternative Towards Affordable Transportation) promotes setting up CBG production plants, bio-CNG plants, and waste-to-energy technology to support India’s renewable fuel goals.

13. What is the role of Super Napier grass and Napier grass seeds in biogas?

Super Napier grass is a high-yield bioenergy crop. Farmers and CBG developers use Napier grass and Napier grass seeds as a steady biomass feedstock for biogas and biogas from Napier grass projects.

14. What factors affect biogas production?

Key factors include feedstock quality, carbon-to-nitrogen ratio, pH and temperature, presence of bioenzymes, mixing arrangement, digester type (such as dry anaerobic digestion process or low-solid digester), and proper pressure monitoring.

15. What is the biomethanation process?

The biomethanation process is the controlled anaerobic digestion of organic waste to produce biogas. It is used for biomethanation of agricultural and municipal wastes, waste processing plants, and industrial waste treatment.

16. What is the role of a transfer station in waste handling?

A transfer station temporarily holds waste before it is moved to biogas plants, material recovery facilities, or waste processing plants, improving efficiency in urban waste management sectors.

17. Can waste-to-energy technologies produce sustainable aviation fuel (SAF)?

Yes. Advanced renewable energy solutions and sustainable aviation fuel technologies convert biomass and waste to energy. Many sustainable aviation fuel companies in India and globally explore biomass feedstock for SAF production.

18. Who are leading biogas plant manufacturers in India?

Several biogas plant manufacturers in India and compressed biogas plant manufacturers deliver turnkey solutions for MSW, agricultural waste, and industrial waste-to-energy projects.

19. What is Organic Recycling Systems?

Organic Recycling Systems is a waste management company and waste recycling company in India offering waste audits, EPC and PMC services, CBG plant development, biomethanation plants, recycling technologies, and waste recovery solutions.

20. What is waste reclamation?

Waste reclamation involves recovering valuable materials and energy from waste using anaerobic digestion wastewater treatment, dry anaerobic digestion, material recovery facilities, composting, and biomethanation.

21. What is the cost of setting up a CBG plant in India?

CBG plant cost in India depends on feedstock type, technology (wet AD, dry AD, biomethanation), capacity, land, and equipment. Costs are typically detailed in a CBG plant project report or feasibility study.

22. How does organic waste recycling work?

Organic waste recycling involves waste collection, analysis by waste audit companies, dry waste segregation systems, anaerobic digestion, composting, and conversion into CBG, compost, and organic fertilizer.