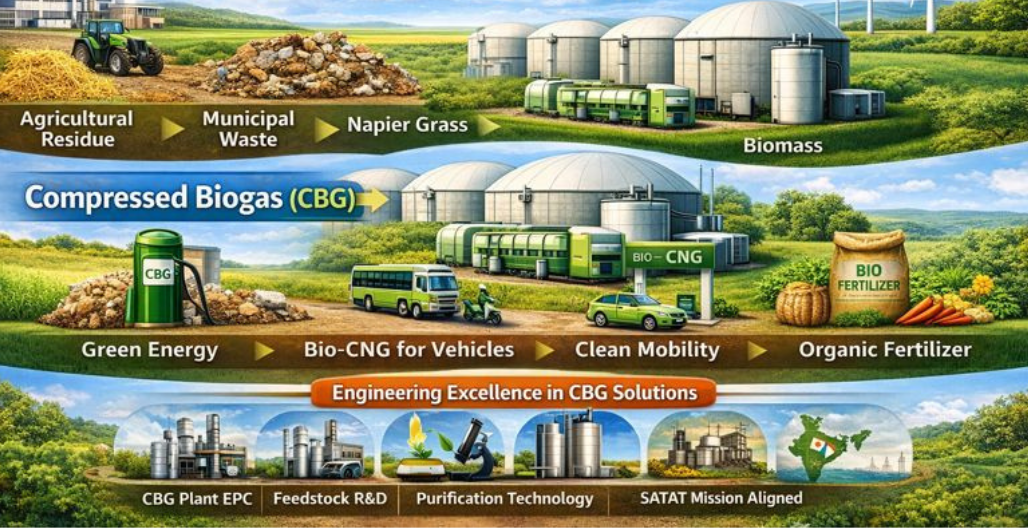

Sustainable waste management is the critical pillar supporting environmental protection, energy security, green mobility, and and circular economy of India. The conversion of agricultural residue and biomass waste, as well as municipal solid waste, into compressed biogas (CBG) happens to be among the most impactful solutions in waste-to-energy today.

As a leading Organic Recycling Systems Limited, ORS is actively driving this transformation by delivering advanced CBG plant engineering, EPC services, and feedstock R&D aligned with national missions like SATAT.

The Role of Compressed Biogas in Sustainable Waste Management

Compressed biogas is a clean, renewable gas derived from organic waste streams of agricultural residue, Napier grass, paddy straw and municipal waste. It substitutes fossil-based fuels while enabling renewable gas from waste.

The key advantages are:

- Landfill dependency reduction

- Sustainable mobility through biogas

- Energy recovery from waste

- Support for green energy from municipal waste

ORS is a CBG technology company in India providing scalable, future-ready solutions for industries, municipalities and developers.

Engineering Excellence: Turnkey CBG Plant Solutions

ORS is recognized as a compressed biogas plant manufacturer in India and a trusted CBG plant EPC company in India, offering turnkey CBG plant solutions from concept to commissioning.

Core Capabilities:

- CBG plant engineering and design

- CBG plant process design

- CBG purification technology

- CBG plant automation solutions

- CBG yield optimisation

- Dry anaerobic digestion systems in India

- Biogas plant with DRYAD system

This integrated approach positions ORS as the best CBG technology company in India for high-efficiency and reliable biogas infrastructure.

Napier Grass: A High-Yield Feedstock for CBG

Napier grass develops very fast with high yields of biomass per hectare, besides giving good methane potential. Among all the bioenergy crops that can be used for biogas, it proves to be one of the best suited CBG crops.

ORS leads innovation in:

- Napier grass biogas production

- Compressed biogas from Napier grass

- Biogas from Napier grass in India

- High-yield feedstock for CBG

- Napier grass for biogas

- ORS Napier grass R&D

By optimizing feedstock R&D for compressed biogas, ORS ensures consistent gas output and long-term plant sustainability.

Biomass, Agricultural Waste & Advanced Conversion Technologies

ORS develops advanced pathways for:

- CBG from biomass waste

- CBG from agricultural waste

- Biomass to CBG

- Biomass to rDME

- Biomass to Sustainable Aviation Fuel (SAF)

Specialised Technologies:

- Paddy Straw Hydrolysis

- Bioenzyme for the pretreatment of agricultural residue

- BM-Alg Technology

- Biological Carbon Capture and Utilisation system (BioCCUS).

MSW & Advanced Thermal Pretreatment

ORS integrates:

- MSW torrefication / MSW torrefaction

- Biomass torrefaction

These pretreatment methods enhance fuel quality, reduce moisture, and improve downstream digestion or energy recovery—supporting waste-to-energy cleantech company India initiatives.

Supporting India’s SATAT Mission

ORS is an active SATAT scheme CBG developer, enabling:

- CBG projects under SATAT

- Long-term offtake readiness

- OMC-compliant plant design

- Regulatory and DPR support

Through multiple ORS projects, the company contributes to national goals of energy independence, farmer income enhancement, and carbon reduction.

Why ORS for Sustainable Waste Management?

- Proven engineering company for CBG

- End-to-end ORS EPC biogas plant execution

- Strong R&D-driven feedstock optimisation

- Expertise across agricultural, biomass, and MSW streams

- Future-ready solutions for renewable gas and green fuels

Conclusion

Waste management has emerged as one of the prime necessities to support India’s clean energy targets. Effective waste management! Environmental issues give us sleepless nights and keep nagging at our consciences if we do not act on them, so here is an action- turning organic and municipal waste into compressed biogas which, apart from addressing environmental issues also provides a steady indigenous renewable fuel source.

Technical strength, continuous research and practical implementation experience have positioned Organic Recycling Systems Limited(ORSL) as one of the developers of efficient waste to energy infrastructure that supports sustainable gas solutions and the foundation for a cleaner circular energy economy in India.

Connect with Organic Recycling Systems

📞 Contact: 022-41702222

✉️ Email: info@organicrecycling.co.in

1. What makes ORS projects different from conventional biogas plants?

Organic Recycling Systems Limited projects are designed with a strong focus on long-term operability rather than short-term installation. Each project integrates feedstock R&D, scalable digestion architecture, automation-ready systems, and future fuel adaptability (CBG, rDME, SAF).

2.Why is Napier grass preferred for biogas and CBG plants?

Napier grass is preferred because it delivers:

- High biogas yield per hectare

- Multiple harvest cycles annually

- Stable digestion performance

- Compatibility with dry anaerobic digestion systems

ORS conducts dedicated Napier grass biogas production and feedstock R&D to optimise gas yield and plant efficiency.

3. What services does a CBG plant EPC company in India provide?

A professional CBG plant EPC company in India provides:

- Feasibility studies and DPRs

- CBG plant engineering and design

- Turnkey CBG plant solutions

- Procurement, construction, and commissioning

- CBG purification technology

- Automation and performance optimisation

ORS delivers complete CBG plant process design and EPC execution under a single responsibility model.

4. How does ORS optimise CBG yield and plant performance?

ORS applies:

- Feedstock R&D and optimisation

- BM-Alg Technology

- Biological Carbon Capture and Utilisation

- Advanced automation and monitoring systems

These innovations ensure high gas yield, stable operations, and long-term plant sustainability.

5. Why choose ORS as an engineering company for CBG projects?

ORS combines:

- Proven EPC expertise

- Strong R&D in bioenergy crops and feedstock

- Advanced digestion and purification technologies

- Experience across agricultural, biomass, and MSW projects

This makes ORS one of the best CBG technology companies in India for scalable and future-ready waste-to-energy solutions.